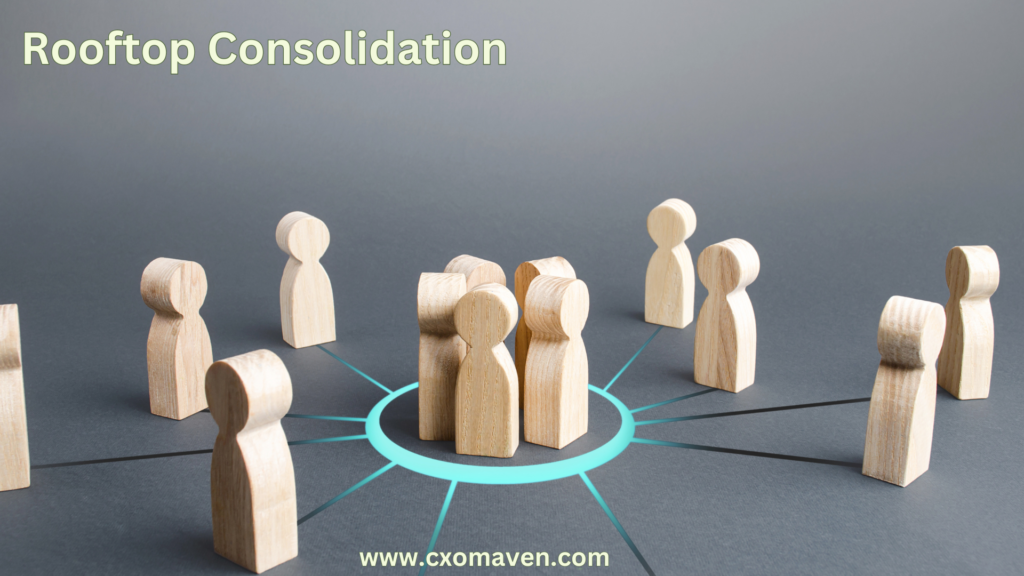

Simplification of the supply chain for a healthcare client by consolidating distributors across all manufacturing sites in India. The goal was to streamline sourcing, reduce costs, and enhance efficiency. This case study outlines the scope, approach, and outcomes of the distributor consolidation initiative.

Scope

The project focused on sourcing across all India manufacturing sites. It involved authorized distributors as well as stockists, covering:

- 2043 Parts: Totaling a $13 million spend across three sites.

Approach

The project followed a structured approach to achieve the consolidation:

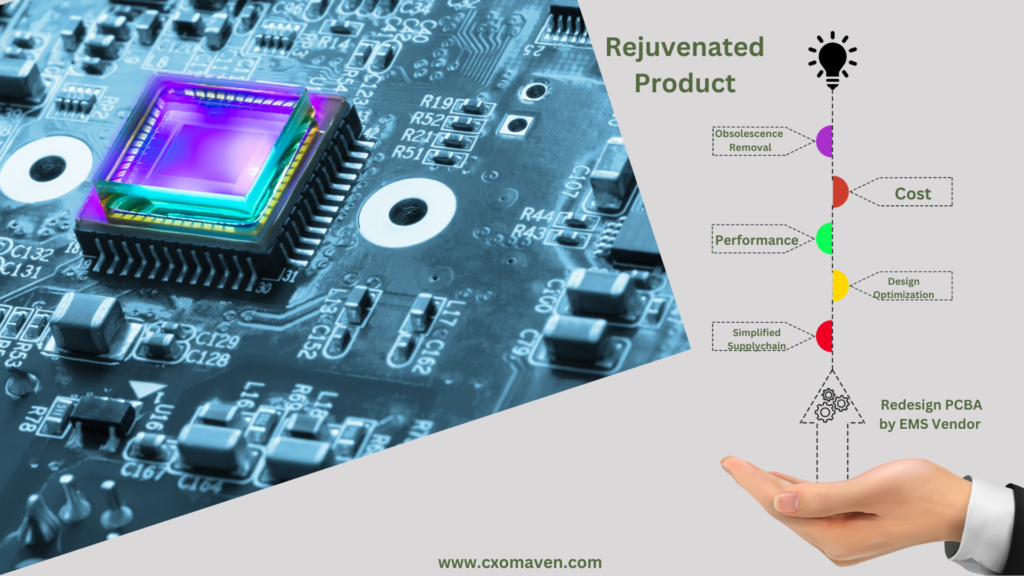

- Define Landscape and Formulate Strategy:

- Identified strategic distributors through Request for Quotations (RFQs).

- Identify Key Parts:

- Targeted parts from manufacturers where direct relationships already existed.

- Freeze on Distributors:

- Selected distributors based on pricing, line-card compatibility, and geographical considerations.

- Plan PIPO with Materials Team:

- Developed a detailed Plan for Implementation and Product Obsolescence (PIPO) with the materials team.

- Execution:

- Implemented the consolidation plan in phases.

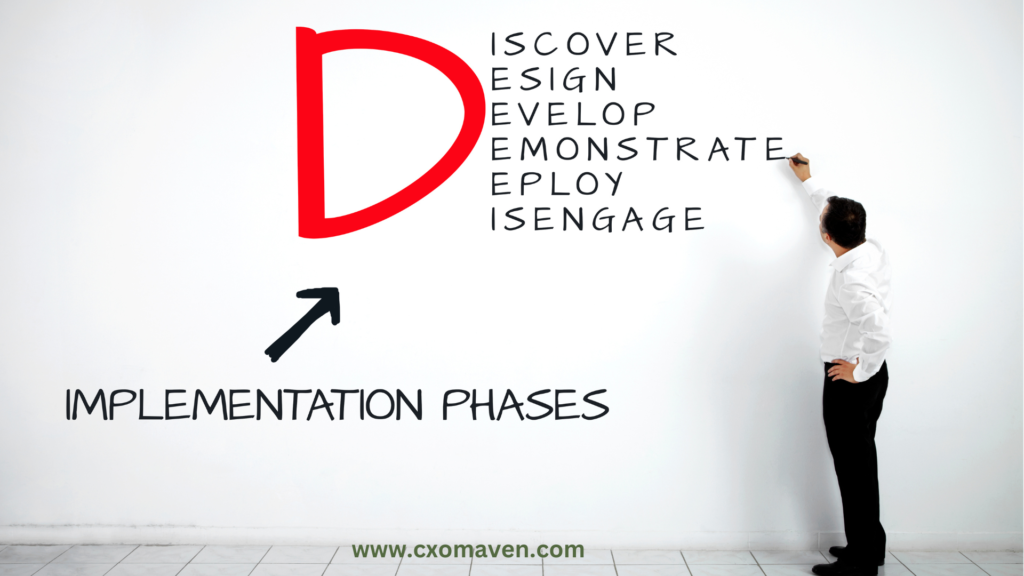

Phases of Implementation

Starting Point (January)

- Distributors: 25

- Parts per Distributor: 82

- Annual Spend per Distributor: $0.5 million

Phase 1 (June)

- Distributors Reduced to: 12

- Parts per Distributor: 170

- Annual Spend per Distributor: $1.1 million

- Reduction in Number of Distributors: 52%

Phase 2 (August)

- Distributors Reduced to: 9

- Parts per Distributor: 227

- Annual Spend per Distributor: $1.4 million

- Reduction in Number of Distributors: 64%

Outcomes

The distributor consolidation project led to significant improvements and efficiencies in the supply chain:

- Distributor Reduction: Reduced the number of distributors from 25 to 9, achieving a 64% reduction.

- Leveraged Relationships: Leveraged stronger relationships with fewer distributors, resulting in increased buying power.

- Global Supplier Count Reduction: Tied in with global suppliers, further simplifying the supply chain.

- Annualized Productivity Savings: Achieved annualized productivity savings of $300K.

Key Wins

- Simplified Supply Chain: Streamlined the supply chain by reducing the number of distributors and increasing parts per distributor, leading to greater efficiency.

- Cost Savings: Significant cost savings were realized through better pricing and consolidated buying power.

- Improved Supplier Relationships: Strengthened relationships with key strategic distributors, resulting in better service and reliability.

Conclusion

This case study demonstrates the effectiveness of distributor consolidation in simplifying the supply chain and achieving significant cost savings for a healthcare client. By reducing the number of distributors and leveraging stronger relationships with key suppliers, the project enhanced operational efficiency and provided substantial financial benefits.

Acknowledgements

The successful implementation of this project was due to the collaborative efforts of the sourcing, materials, and procurement teams, who worked closely with distributors to achieve the desired outcomes.

Future Plans

Building on the success of this project, the organization plans to:

- Expand the consolidation efforts to other regions and categories.

- Continuously review and optimize the distributor base to ensure sustained cost savings and efficiency.

- Enhance supplier collaboration through regular reviews and strategic partnerships, ensuring a resilient and streamlined supply chain for future growth.