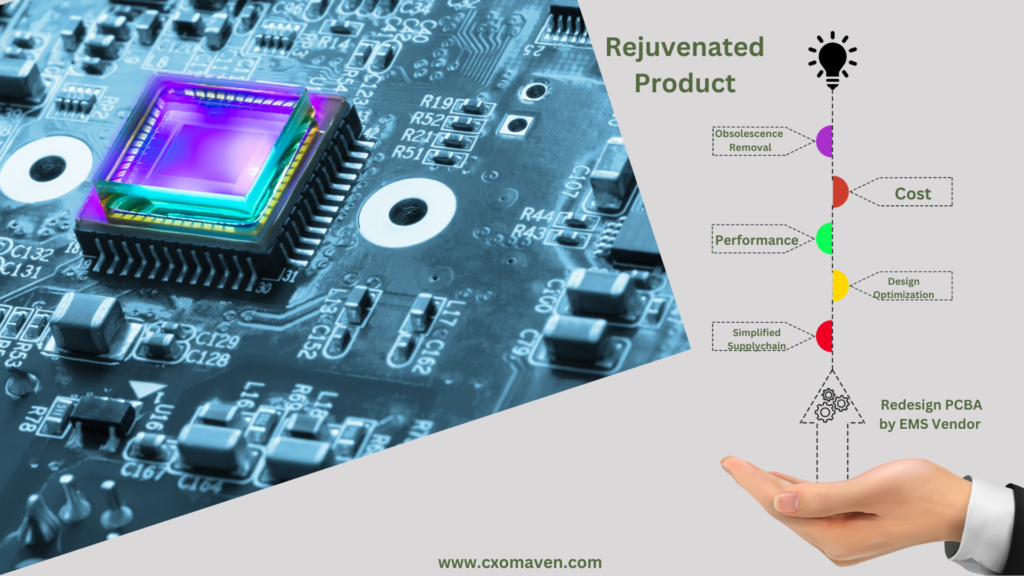

Redesign of PCBAs (printed circuit board assemblies) by collaborating with Electronic Manufacturing Services (EMS) providers to achieve new product introduction, significant cost reductions, remove obsolescence, improve product performance, and enhance supply chain efficiency for a healthcare client.

Background

The healthcare client faced challenges in optimizing the design and production of PCBAs used in various medical devices. The project aimed to leverage the design capabilities and resources of EMS providers to achieve cost savings and improve the quality and reliability of the PCBAs.

Methodology

The project followed a structured approach, focusing on collaboration with EMS providers and utilizing their expertise in redesign and manufacturing processes.

Supplier Collaboration

- Design Capabilities: Engaged EMS providers with design capabilities in embedded, digital, power electronics, and RF domains.

- Completed Redesigns: Achieved a 3-8% cost reduction in completed redesigns, resulting in total annual savings of $1 million.

- Ongoing Redesigns: Targeted a 5-8% cost reduction in ongoing redesigns, with projected total annual savings of $2 million.

- Cost Reduction: Achieved an average cost reduction of 35-40% across various components.

- Supplier Engagement: Engaged supplier resources at multiple locations, including visiting Engineering sites in the US and Europe, for pilot qualifications and redesign activities.

Building Trust for Capabilities

- Cleveland : Conducted multiple short-term assignments with a duration of four months for pilot qualification and design improvements.

- Maryland : Completed pilot qualification in two months, demonstrating rapid turnaround and effectiveness to customer.

- October 2020 : Conducted a prototype pilot qualification in two months, focusing on the transition to BOS creation and redesign/DFM inputs.

- Supplier Participation : Suppliers participated in “Supplier Day” events, demonstrating commitment to the project and potential for facility takeovers and redesigns.

Redesign Projects

The project included several successful redesign initiatives, collaborating with EMS providers identified as Supplier 1 and Supplier 2.

Completed Projects

- ECG Machine PCBA Redesign

- Business : DCAR

- Key Improvements:

- Integrated modern power supply

- Obsolescence risk mitigation

- Two months turnaround time

- VTC Y 5^4

- Vitality increased by 73%

- Outcomes:

- Significant cost savings and improved reliability

- PET machine PCBA Redesign

- Modality: PET

- Key Improvements:

- Replaced 16 boards with a single board

- 70% active components reduction

- 100% savings on low volume product

- Outcomes:

- Enhanced reliability and reduced manufacturing complexity

- Portable X ray machine redesign

- Modality: X-ray

- Key Improvements:

- Reliability tests completed

- EMI/EMC tests completed

- 100% active components reduction

- Lead time reduced by 50%

- Achieved 100% savings on low volume product

- Outcomes:

- Improved reliability and reduced costs, product was made suitable for India Market

Outcomes

The collaboration with EMS providers led to significant outcomes:

- Cost Savings: Achieved total annual savings of $3 million from completed and ongoing redesign projects.

- Improved Product Performance: Enhanced the quality and reliability of PCBAs through effective redesigns and rigorous testing.

- Supply Chain Efficiency: Streamlined the supply chain by reducing the number of components and integrating modern technologies.

- Rapid Turnaround: Demonstrated the ability to complete pilot qualifications and redesigns within short timeframes, improving overall project efficiency.

Conclusion

This case study highlights the success of redesigning PCBAs by collaborating with EMS providers. By leveraging the design and manufacturing expertise of Supplier 1 and Supplier 2, the healthcare client achieved substantial cost savings, improved product performance, and enhanced supply chain efficiency. The project underscores the value of strategic supplier partnerships in driving innovation and operational excellence.

Acknowledgements

The successful implementation of this project was due to the collaborative efforts of the project team, including sourcing leaders, supplier quality experts, and key stakeholders from Supplier 1 and Supplier 2.

Future Plans

Building on the success of this project, the organization plans to:

- Expand redesign initiatives to other critical components and modalities.

- Continuously review and optimize supplier collaboration strategies to maintain cost efficiency and product quality.

- Foster innovation through ongoing engagement with EMS providers and leveraging their design capabilities for future projects.