Objective

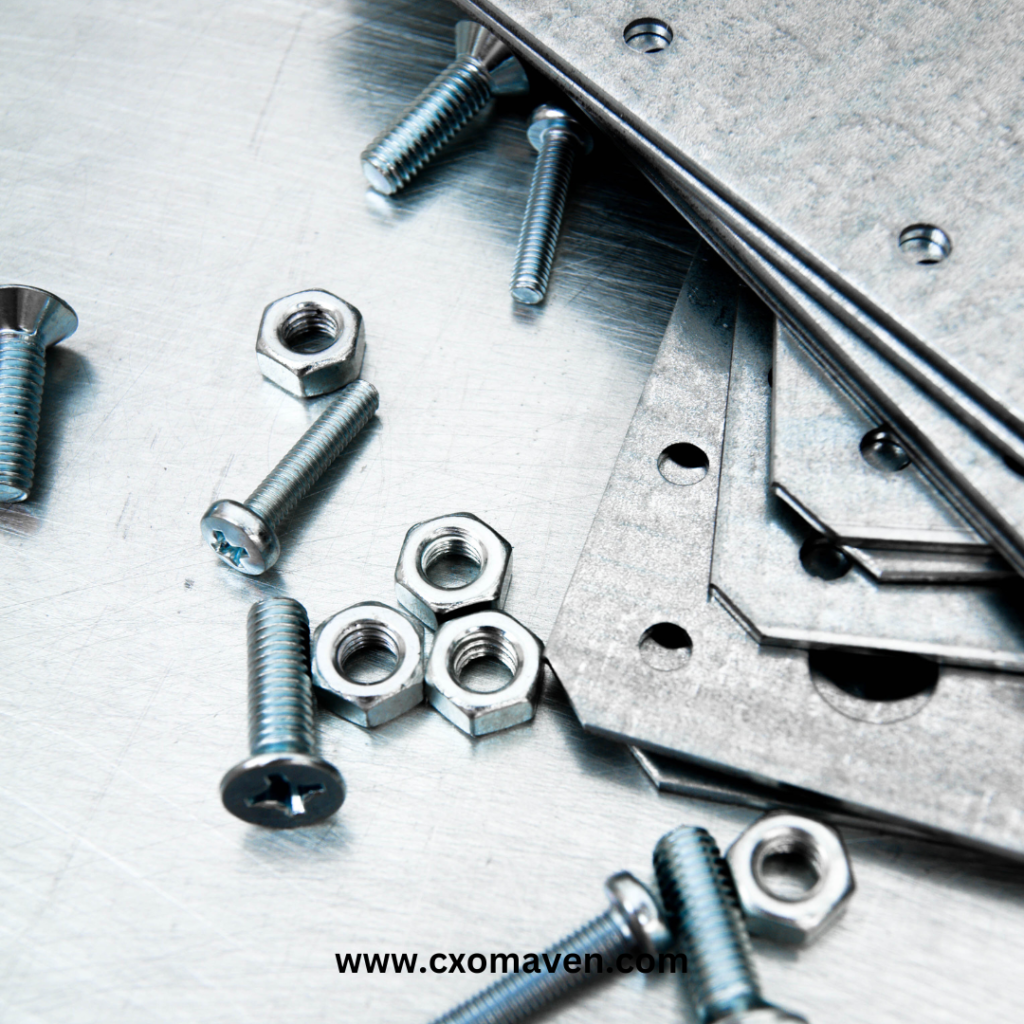

Implement a Should Cost analysis for sheet metal parts sourced from a prominent sheet metal supplier in Bangalore. The goal was to achieve significant cost savings, address challenges related to commodity price increases, and improve supplier collaboration for a healthcare client.

Background

The healthcare client had been facing several challenges with the procurement of sheet metal parts:

- Commodity Prices: Rising commodity prices were affecting the overall cost of parts.

- Aging Parts: Some parts were becoming outdated, necessitating a review of their costs and procurement strategies.

The client sourced 392 parts across 7 business verticals, with an annual spend of $2.1 million on these components. A detailed Should Cost analysis was deemed necessary to identify cost-saving opportunities and optimize procurement.

Methodology

The project followed a structured approach, focusing on high-value parts and utilizing Lean Six Sigma DMAIC methodology:

Define Phase

- Scoping of High-Value Parts: The team identified high-value sheet metal parts that were critical to the client’s operations and had the potential for significant cost savings.

Measure Phase

- Data Collection: Detailed cost data and cycle time information were collected for each identified part.

Analyze Phase

- Should Cost Analysis: A comprehensive Should Cost analysis was conducted, including cycle time studies, to establish the benchmark costs for the parts.

- Comparison: The current prices were compared with the Should Cost estimates to identify discrepancies and potential savings.

Improve Phase

- Supplier Engagement: The team engaged with the prominent sheet metal supplier in Bangalore to discuss the findings and negotiate better pricing based on the Should Cost analysis.

- Paradigm Shift: Efforts were made to shift the supplier’s mindset towards embracing the Should Cost approach, leading to more open and collaborative negotiations.

Control Phase

- Ongoing Monitoring: Regular reviews and monitoring were established to ensure that the cost savings were sustained and further opportunities for improvement were identified.

Outcomes

The implementation of the Should Cost analysis led to significant outcomes:

- Traditional Method: Initially, using the traditional method, the supplier offered a material cost reduction of $71,000, representing a 3.4% savings.

- Should Cost Methodology: By embracing the Should Cost methodology, the savings increased to $145,000, representing a 6.9% reduction in material costs.

Specific cost-saving achievements included:

- Inverter Sheet Metal (CT line of business ):

- Previous Price: $47.78

- Should Cost: $25.35

- Material Cost Reduction : $27.5K (47%)

Key Wins (Should-Cost Approach)

The project not only resulted in direct cost savings but also brought about several key wins:

- Supplier Mindset Shift: The supplier adopted a more open approach to the Should Cost methodology, leading to more transparent and collaborative negotiations.

- New Business Opportunities: The successful implementation of the Should Cost approach paved the way for new business in the biosciences sector, resulting in an additional $110K in savings for the client.

Conclusion

This case study demonstrates the effectiveness of the Should Cost analysis in driving significant cost savings and improving supplier collaboration for a healthcare client. By focusing on high-value parts and engaging a prominent sheet metal supplier in Bangalore, the project achieved substantial financial benefits and operational efficiencies.

Acknowledgements

The successful implementation of this project was due to the dedicated efforts of the project team, including sourcing leaders and supplier quality experts, who worked closely with the supplier to achieve the desired outcomes.

Future Plans

Building on the success of this project, the healthcare client plans to expand the Should Cost analysis to other critical components and suppliers. Continuous improvement initiatives, including regular cost reviews and supplier engagements, will be maintained to ensure sustained cost efficiency and operational excellence.